As long as RVs have been around, this question has been around: How do you know if an RV is well-made? Reason alone would suggest that their must be some chief indicators of an RV model’s build quality. And reason, as you might have guessed, is right. The trouble is that RVs are composed so many different systems that assessing each one can feel exhaustive. So, what’s a buyer to do?

Well, I have good news and grown-up news. The good news is that they’re definitely are some indicators you can look for that speak to an RV model’s build quality. These are great places to start — and looking for them in a model can help you assess your interest more quickly. However, once you’ve narrowed your list with model’s whose build quality you trust, then you get the grown-up news: You still need to assess your whole RV. (But now, you’re doing that between a few models, so it’s less scary.)

So, let’s get started. But first, an important word on how RVs are put together.

Clue-in on the RV Manufacturing Process and Components

RVs are made up of components from a variety of suppliers. Those suppliers have a range of products from affordable to exceptional. There are absolutely higher-quality components and those that are more price-focused.

RVs are almost completely hand-built in a big hurry. (There is almost no automation in RV manufacturing.) Some companies tend to keep team members for a long time, others don’t. Those companies who do have team members that stay a while also tend to have fewer issues with errors being made in installation.

What I always recommend is starting at the underside of an RV before even stepping inside. This is where an RV company can specify high-quality components or more price-focused pieces.

Ask About the Manufacturer’s Testing Process

Since RVs are mostly hand-built, one of the ways to make sure all the team are in line with the changes and production systems is to find out what kind of testing a company will do as part of their build process.

I’ve been to a lot of RV assembly lines. Frankly, there is a huge difference in how the team works together — as well as the processes put in place to enable them to be at their best. It’s really telling, to me, to see team members joking and working together in a harmonious fashion. But recently there’s something that I’ve seen. In some RV factories, they are extensive testing either along the production line or at the end of the line. Certain companies do both.

So, one of the ways to see how your RV is built is to reach out to the manufacturer and find out what all testing the company does as part of the production process. Companies that have processes that they’re proud of will likely gladly share those processes with you.

Here are some, but not all, examples of things I’ve seen in doing RV factory tours.

Examples of Manufacturer Testing

We had the chance to visit with Jayco to review some units there, and I also got to go to one of their predelivery inspection (PDI) testing facilities. Jayco has several purpose-built facilities to test every unit built before it is delivered to the customer.

I have also been to the Rockwood/Flagstaff facility. There, the company has a special door insert that pressurizes the RV with air. Then team members spray soapy water on the exterior looking for leaks. I also have seen them hook the propane and water systems up to pressure and test to make sure those systems can hold pressure.

At Alliance RV, the company has installed shaker tables and each RV coming off the line is parked on a shaker tables. These tables shake the rig to make sure it holds up to the shaking. And at ATC, they have a rain booth where the trailers are subjected to the equivalent of a strong rain storm, again to check for leaks.

Start with the Suspension

Looking at an RV itself, as mentioned, I aways recommend that buyers start from the road up. The suspension is an area where RVs can significantly differentiate from one another.

If you’re choosing a motorhome, and it’s a Ford motorhome or E-Series chassis, these can be pretty harsh. Some companies will step up the ride and handling using an upgraded suspension and/or steering system. If you’re looking at a gas-powered motorhome based on the Ford chassis, companies that upgrade these usually make a big deal about the upgrade as it is expensive.

As for towables, the cheapest suspension you can get is a leaf spring suspension with dry bolts. These offer very little compliance and don’t eliminate a lot of the harshness that can be transmitted from the road. Further, the lack of a greaseable fitting means that they can experience wear rather quickly.

Upgrades and Technology

Some RV companies will upgrade their trailer suspensions with improved shock dampening components. This means fewer shocks are transmitted into the trailer itself. Ultimately, that can help it last longer. Also, there are a few companies who provide greaseable fittings on their suspension which also helps with longevity, provided you regularly inspect and grease these components. You wouldn’t even consider driving a vehicle without shock dampening which, on a vehicle, is a shock, absorber but most trailers have little or no shock dampening in their suspensions whatsoever.

There are a few technologies that do provide improved shock dampening including a torsion-axle suspension. This is a unique suspension that mitigates vibration and harshness. Nicely, it also requires little maintenance.

A step up from this is Curt’s trailing coil suspension. It uses coil springs and shocks at each wheel to provide exceptional towing while lessening road irregularities. However, these systems require a beefier frame and are pricey. So, you don’t see many RVs with them, but they are available to manufacturers for both fifth wheels and travel trailers.

Get a Look at the Plumbing

One of the biggest sources of headaches for RVers is in the plumbing department. While virtually all RVs now use PEX plumbing, which is good, there’s more to it than that. In many cases, RVs use flexible lines in some places but with PEX clamps. You will find no shortage of complaints about this in any RV-related forum. There are now some companies using different connectors for these flexible hoses.

A very few RVs actually have shut-off valves for each fixture so that, if there is a plumbing issue, you can disable that one fixture and camp on. This is ideal.

Inquire About Wall Construction

There are essentially three main ways RV companies build RV walls. Some use a wood frame with an aluminum skin. Others use a number of layers in a lamination process. And still others use fiberglass molds for the entire wall structure. There are some pretty significant variations among these broader categories. (Of course, there’s also the aluminum build that Airstream uses.)

Azdel! What Does That Even Mean?

The biggest variety of processes is in laminated walls where all manner of components and glue can be used to build a wall. You may have come across the term “Azdel” when referring to RV walls. Azdel is a man-made sheet that is impervious to water damage. It also provides some benefit in sound insulation.

There are now competitors to Azdel for this product as well. Essentially, the product is used beneath the surface of the fiberglass exterior layer and offers the benefit of not being damaged if there is water intrusion.

Laminated Walls

For laminated walls, typically the layers are fiberglass. Nexta substrate (this is where Azdel would come in). Then either an aluminum rib or foam insulation. And then another substrate layer and then the interior wall board. There are some cases where the interior wall is the entire inner layer.

Traditionally, lauan had been used as the substrate. However, this material can be damaged if water gets into the walls. You will likely find that, if a company uses a man-made substrate, they’re pretty proud of this and it will appear on the marketing materials for the RV.

Considering Future Repairs

I like the laminated wall but know that, if it’s damaged, it’s difficult to repair. It does offer good strength to weight advantages. There are a ton of different variables with this, too. These can include the quality of the glue the company uses, the process by which the lamination itself is done, and more. I have found that when a company is diligent in some of the processes that you can see, they tend to be more diligent in the processes you can’t. (Like wall builds, although this is a big generalization. )

Aluminum-skinned wood-framed trailers (stick-and-tin) are the least expensive to build. This traditional process isn’t bad at all but know that it’s more challenging to seal. Properly maintaining these seals will prevent water intrusion which can destroy any RV.

Companies like Casita are famous for making trailers like boats using a fiberglass mold. These have far less chances of water damage.

Inspect the Roof

Another place to look is the roof. It’s very common that RVs are built with a rubber-like membrane on the roof. And some of these carry a lifetime warranty. Still, the sealants used around the breaches in the roof for things like vents and antennae and that sort of thing do not.

You can see how well a sealant was applied, which is another indicator of how the RV is built overall. All these seals are also something to routinely inspect. They can last for years with no issues or need attention on a somewhat routine basis. The manufacturer of the RV will specify what should be used to maintain these seals.

Open All the Cabinets

The quality RV cabinetry varies tremendously. Some RVs use very, very inexpensive cabinetry, and others really go the extra mile. Stepping into an RV and opening a drawer, you can easy see the caliber of cabinetry a company uses.

But there is more than meets the eye. In some cases, RV companies will use very high quality hardwood cabinet doors and drawer faces, but then use sticker-wrapped wood composite stiles and bases for their cabinets.

How to Inspect Drawers and Cabinets

One way to tell how the cabinet structure is built is to take your phone and look at the back side of the cabinets. On many RV cabinets you will see the fancy appearance come to an end and what looks like a smooth particle board take its place. These are sticker-wrapped MDF cabinets.

Another place to look is how the cabinet and drawer structures are joined and finished. I’ve seen plenty of drawer boxes that are unfinished and stapled together. Some are nicely finished and stapled together. Very few drawer boxes actually have a dovetail construction, which is the best.

Don’t Forget These Spots

Other places you can see how the RV is built is by lifting the bed or looking under cushions. In some cases, it looks almost like the company used spare palettes to build the furnishings. Other times, you’ll be really impressed with a higher quality build. And there are some companies who build dinette and bed bases out of welded aluminum, which is more costly but offers good strength and light weight.

You can also see how far the drawers extend and what type of drawer slide mechanism is used. Nowadays, many RVs use ball-bearing glides, but there is a difference in the weight carrying capacity of these glides. There are also a few that are under the drawer box itself. (So you don’t even see the glide.)

Measure That Kitchen Oven

While many RV appliances found in your galley come from one or two major suppliers, those suppliers offer a variety of grades of appliances. A common way companies save money is by specifying a small 17-inch (vertical) oven. I write about this often in our independent RV Trader reviews, but it simply does a very poor job of cooking with hot spots and limited space. There is also a larger 21-inch oven, which I have used to roast a prime rib. (It performs well.) The cooktops are relatively standard until you start hitting the upper end of the price spectrum.

Know that you’re almost guaranteed to get a 12-volt compressor fridge in any RV nowadays. These have improved remarkably and are specially designed for life on the road. (I have an article where I tested a new 12-volt fridge’s efficiency.)

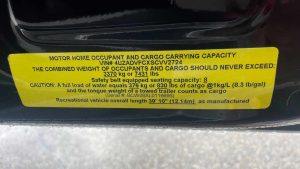

Don’t Neglect the Data Plate

One last area to look at is with data plate on the RV. All new RVs have to have one. This will show you how much cargo the RV can carry. It spells it out fairly clearly. You should know that there should be sufficient cargo carrying capability to reasonably accommodate the things you’d normally bring camping. Some RVs are built so close to capacity that there is little accommodation for your stuff. (This is particularly true in some Class C motorhomes, but not all.)

Allow RV Build Quality to Refine Your Shopping List

RVs are beautiful, and the adventure promised is incredible. So, admittedly, it’s easy to get swept up in the vision of adventure when shopping. Still, looking just a bit below the surface can tell you a lot about an RV model’s build quality. And that’s important, because the fact is that there are absolutely some RVs built better than others. Choosing wisely can really set a great course for less stress, more adventure in an RV that does what you bought it for.

Leave a Reply